1 2 3 4 5

1 2 3 4 5

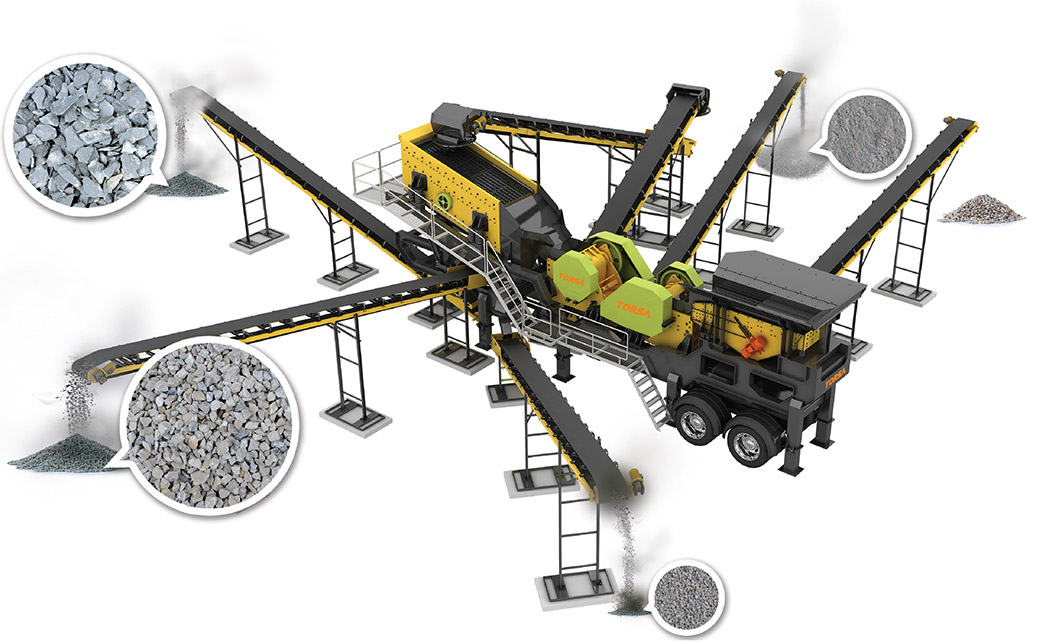

Designed for operations ranging from 40 to 70 TPH, the C4 and C7 models are a pinnacle of compact, economical crushing and screening solutions. By integrating all critical crushing and screening components onto a single chassis, the C Series significantly reduces the spatial footprint, making efficient use of site space. Adaptable to various terrains and site conditions, the C Series enhances mobility and optimizes operational costs, standing as a robust, space-efficient, and versatile choice in the crushing and screening sector.

| MODEL | PRIMARY JAW CRUSHER | POWER | MAX. FEED | CRUSHING CAPACITY (TPH) | ||||||||||

| SIZE | CLOSE SIDE SETTING ( CSS ) IN MM | |||||||||||||

| MODEL | KW | MM | 30 | 40 | 50 | 60 | 70 | 80 | 100 | |||||

| C7 | TJC 3020 | 45.0 | 400 | 51 | 61 | 71 | 81 | 102 | ||||||

| C4 | TJC 2415 | 37.5 | 300 | 24 | 32 | 41 | 49 | 57 | 65 | 80 | ||||

| MODEL | VIBRO FEEDER | |||||||||||||

| MODEL | SIZE (MM) | POWER (KW) | CAPACITY (TPH) | |||||||||||

| C7 | TVGF H 800X3000 | 800 (W) x 3000 (L) | 1.9 x 2 | 50 - 100 | ||||||||||

| C4 | TVGF H 800X3000 | 800 (W) x 3000 (L) | 1.9 x 2 | 50 - 100 | ||||||||||

| MODEL | SECONDARY JAW CRUSHER | POWER | MAX. FEED | CRUSHING CAPACITY (TPH) | ||||||||||

| SIZE | CLOSE SIDE SETTING ( CSS ) IN MM | |||||||||||||

| MODEL | KW | MM | 15 | 20 | 25 | 30 | 35 | 40 | 50 | |||||

| C7 | TJC 4808 | 37.5 | 150 | 22 | 29 | 36 | 44 | 50 | 58 | 72 | ||||

| C4 | TJC 2408 | 22.5 | 150 | 11 | 15 | 18 | 22 | 25 | 29 | 36 | ||||

| MODEL | VIBRATING SCREEN | |||||||||||||

| MODEL | SIZE (MM) | POWER (KW) | CAPACITY (TPH) | |||||||||||

| C7 | TVS 125T | 1524 (W) x 3660 (L) | 11.75 | 40 - 80 | ||||||||||

| C4 | TVS 104T | 1220 (W) x 3158 (L) | 5.5 | 20 - 40 | ||||||||||

** ALL CAPACITIES ARE CONSIDERED @ 1.6 T/m3 BULK DENSITY

For any Customer / Service related queries, please contact:

Corporate Office

Torsa Machines Limited

Ambuja Eco Centre, Plot No - 04,

EM Block, Salt Lake, Sector V

Suite No. 703, 7th Floor, Kol 700 091

West Bengal, India

Works Guwahati

Export Promotion Industrial Park,

Amingaon,North Guwahati 781 031,

Assam,India

Works Kolkata

Bara Para, Bhagabatipur,

Kandua Panchayat, Sankrail,

Howrah 711 313, WB, India

Email : info@torsa.com

Toll Free : 1800 121 5696